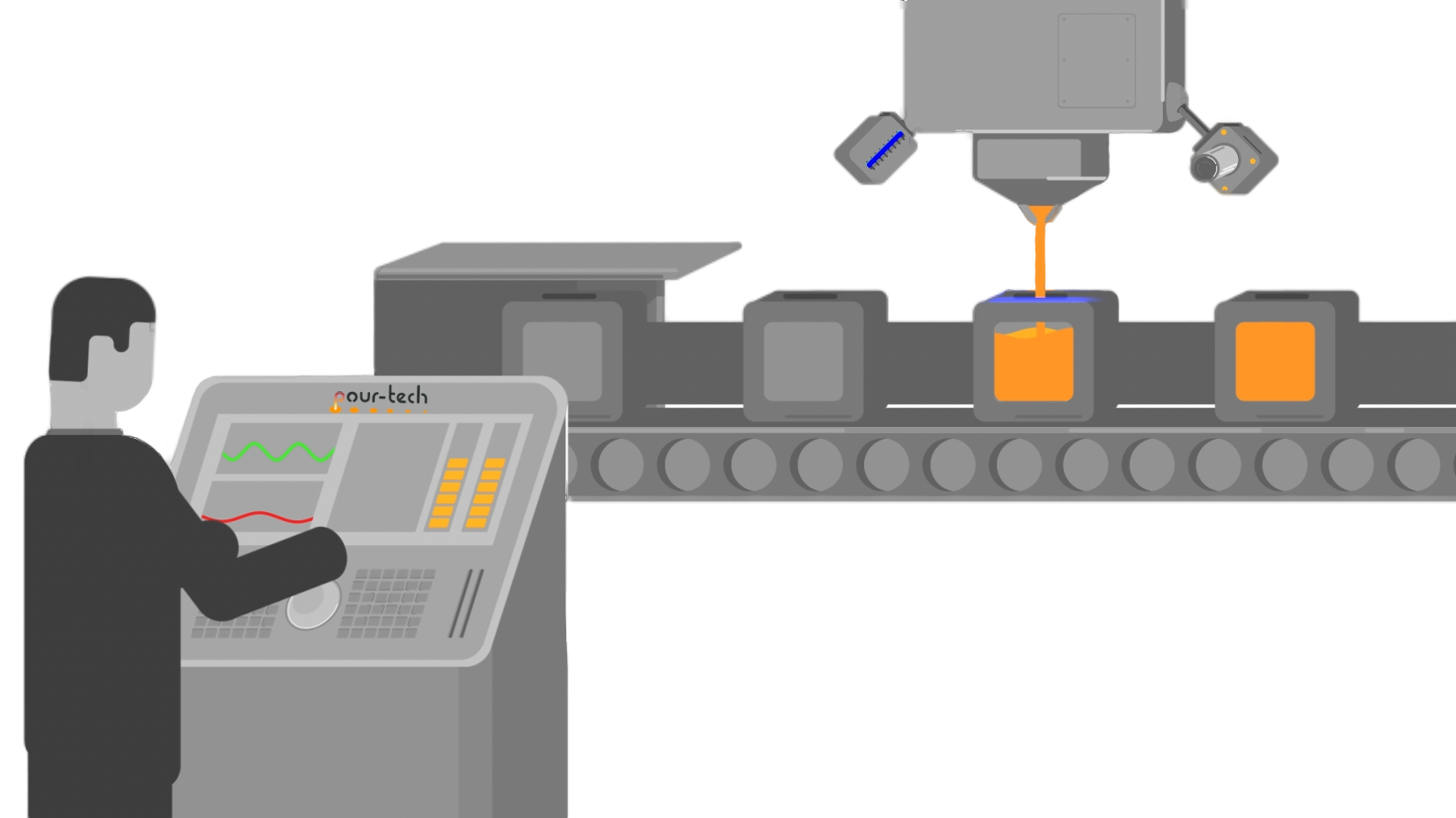

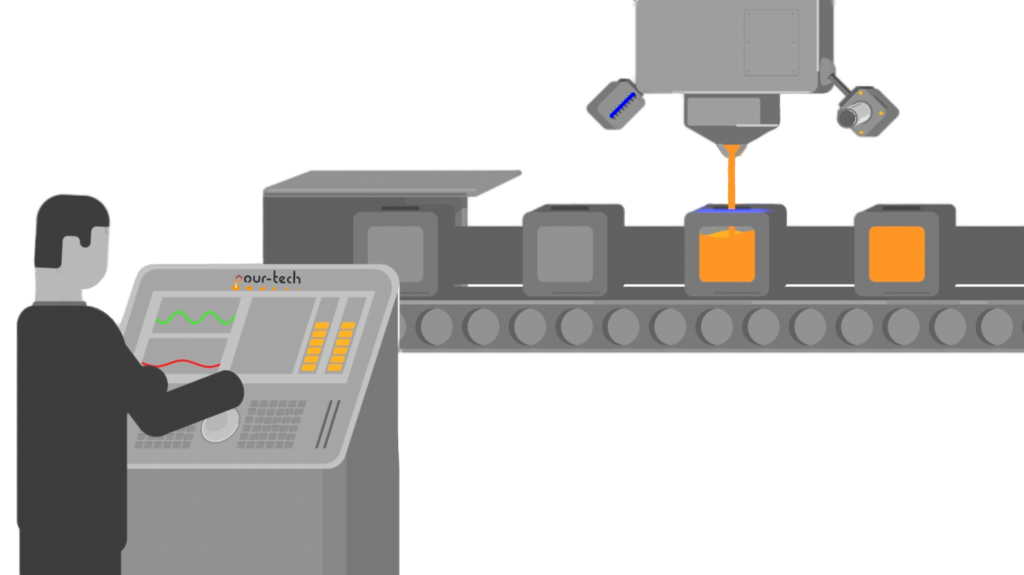

Automatic pouring

Pouring upgrade leading to a fast, independent and accurate process

The automatic pourTECH™ system is equipped with an electric servo drive stopper rod actuator unit, hydraulic, pneumatic, hardware and control systems.

The system operates on horizontal and vertical mold lines, and will perform as follows:

- The PLC controls the flow of molten metal from the nozzle into the mold by opening and closing the stopper. It gets information by the laser to be able to adjust the filling speed. Using the specific parameter stored in a database, the pouring will be performed for each individual pattern.

- A communication with the mold line assures the correct pouring parameter for each mold.

- Operator is released from the basic setup of the pouring. Only adjustements are needed.

- The PLC will position the pouring unit with the nozzle over the pouring cup by a dedicated laser control system.

In case of Mg-treated iron a pneumatic driven stopper twist and plunger can be supplied.

A wide range of functional tools like 3D line laser technology, automatic in-stream temperature control, automatic in-sxtream inoculation, automatic bath level compensation, FORCEpour™, mold mapping, pourTECH™ Database, monitoring systems can be added for quality control.

Profit from automatic pouring

Qualitätssteigerung

By having constant pouring conditions the quality will be improved and the scrap rate can be reduced.

profitable production

Higher output of the foundry due to higher yield.

possibility to upgrade

For a higher level of automation the system is designed to accommodate additional needed sensors and equipment.

relief for the operator

Operators are released from the repeatable work. They can do some other work during the pouring, like temperature measurement and deslagging.

constant pouring time

That means the influence of quality issues by inconstant pouring time can be reduced.

Portfolio of automatic pouring

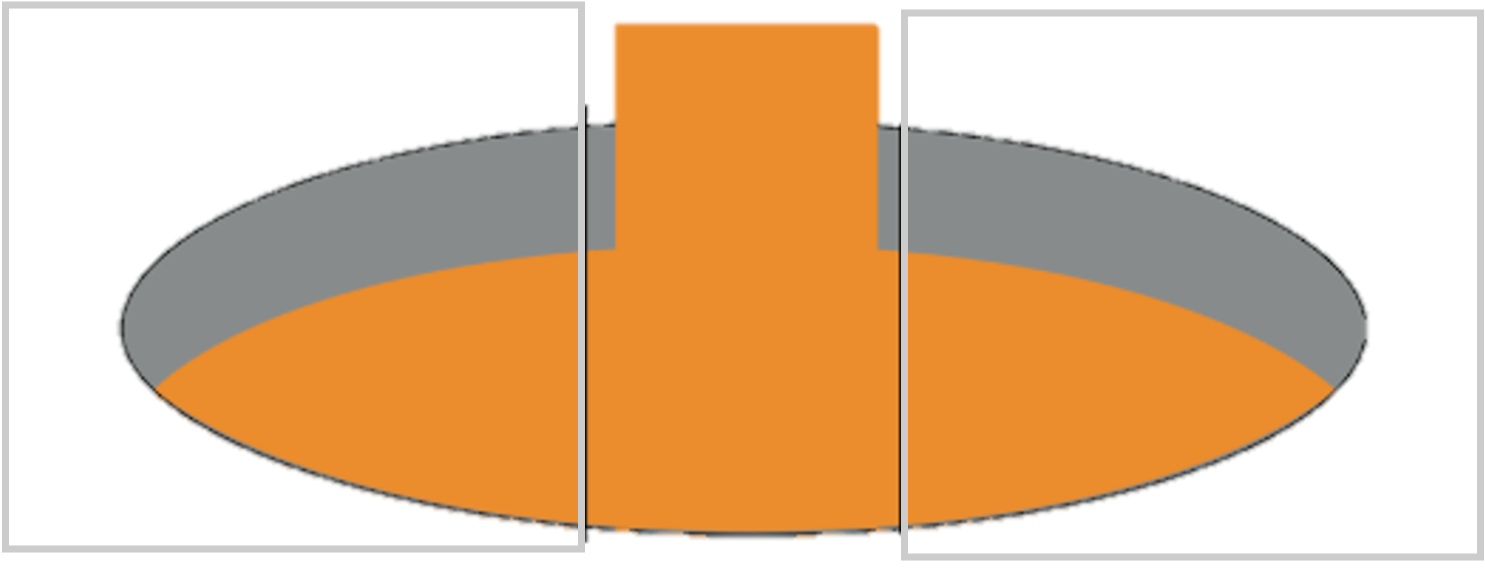

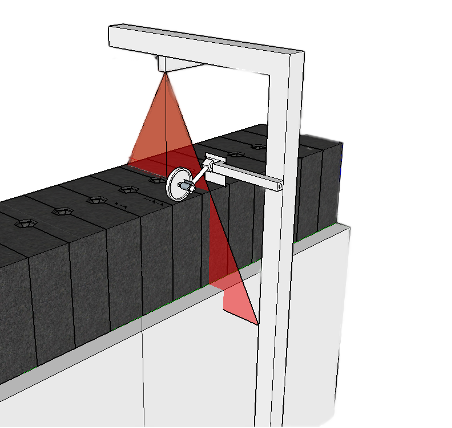

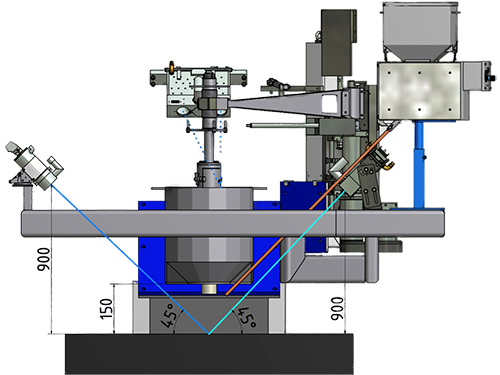

3D line laser™ technology

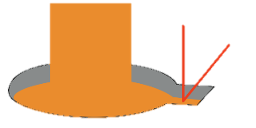

Improvement of yield by reduction of pouring cup size

The 3D Line Laser™ system consists of C-MOS receiver, Line Laser and positioning laser. The line laser generator and 3D sensor are positioned on opposing sides. The laser projects a laser line across the top of the mold. From the opposing side, the C-Mos receiver determines the profile and elevation of the line. The 3-D Laser system finds the pouring cup and then provides real-time metal level feedback to the control system.

The pouring cup size can be reduced to a minimum and leeds to an elimination of the “laser tail”.

- Housed in stainless-steel water-cooled jackets

- Self-contained with closed loop cooling system for optimum operating temperature

- Keeps dirt away from sensor optics by air purge for positive pressure inside

The 3D Line Laser™ is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

Single Point Laser Technology

For pouring solutions with limited space

The Single Point Laser projects a laser dot at the top of the mold. By triangulation principle, the measurement of the level will be performed. The system finds the pouring cup and provides real-time iron level feedback from the tail to the control system.

- Pouring cup needs the “laser tail”

- Stable measurement and high reliability

- Housed in stainless-steel water-cooled jackets

- Self-contained with closed loop cooling system for optimum operating temperature

- Keeps dirt away from sensor optics by air purge for positive pressure inside

The Single Point Laser is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

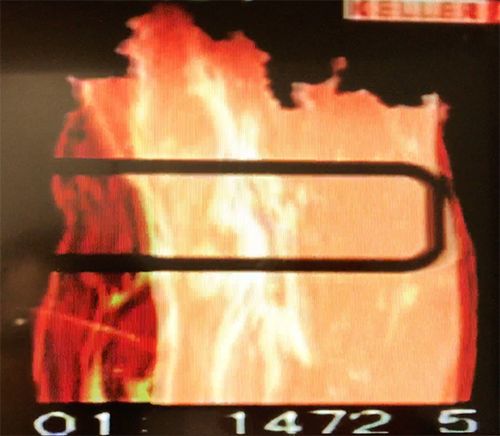

vision technology

For vertical mold lines

with large pouring cups

The video camera is focused on the pouring cup observing the iron level to adjust a constant level while pouring. The sand mold in the back of the iron stream gives the contrast for the camera, no additional or special lighting is required.

The information about the pouring process will send pixel information to the PLC processor for counting the illuminated pixels for calculation of the cup filling.

- Housed in stainless-steel water-cooled jackets

- Self-contained with closed loop cooling system for optimum operating temperature

- Keeps dirt away from sensor optics by air purge for positive pressure inside

The vision technology is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

Automatic in-stream inoculation

for a reliable and real-time inoculation before solidification

For the pouring process the in-stream inoculation is a significant requirement for the casting quality. Our inoculations unit are known for:

- high uptime

- having multiple sensors for reliable operation

- being easy to install

- being easy to calibrate

- the skill to operate with double feeder system with different inoculants

The inoculation unit works with removable hoppers for capacities of 25 or 50 kg, powder grain size of 0.8 mm and density of approx. 1.7 kg/dm3. Feeding rates between 1 – 80 gram/sec are available. The amount of delivered inoculant can be recorded in the database. The HMI screen shows all the significant status information.

The dosing unit also provides automatic error checking, using a variety of sensors to check for:

- Low level in the hopper

- No (insufficient) air supply

- Feeder screw operation

- No inoculation is fed

- Incorrect feed rate

- Incorrect injection pressure

- Blocked inoculation pipe

The in-stream inoculation control is integrated into the automatic pouring control system for full control over the inoculation unit. pourTECH™ makes it possible to individualize the inoculation rate for each job. By controlling the timing of the inoculation signal, pourTECH™ can ensure that the first inoculants reach the pour cup together with the iron so that the entire casting is inoculated.

In addition, the pourTECH™ system monitors all alarms and can provide a quality record for every casting.

The integrated control system allows easy calibration of the feed rate and various monitoring functions and is designed for reliable operation.

The in-stream inoculation is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

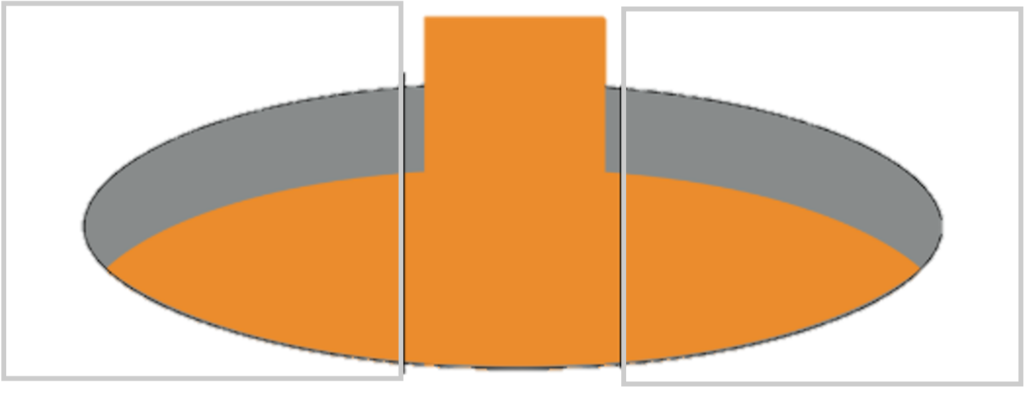

Automatic positioning

By use of 3D Line or Spot Laser the system will perform the Automatic Positioning without the need of installing other equipment. When the cup is detected, the pouring unit will be moved to the correct pouring position.

- An encoder tracks all sand/mold line movements, completely separate from all other systems.

- The sensor is programmed to identify pouring cups.

- The sensor detects the cup while it passes by the scanner and stores its position.

- All cups are analyzed individually for dimension, position and any other possible differences.

The Automatic Positioning is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

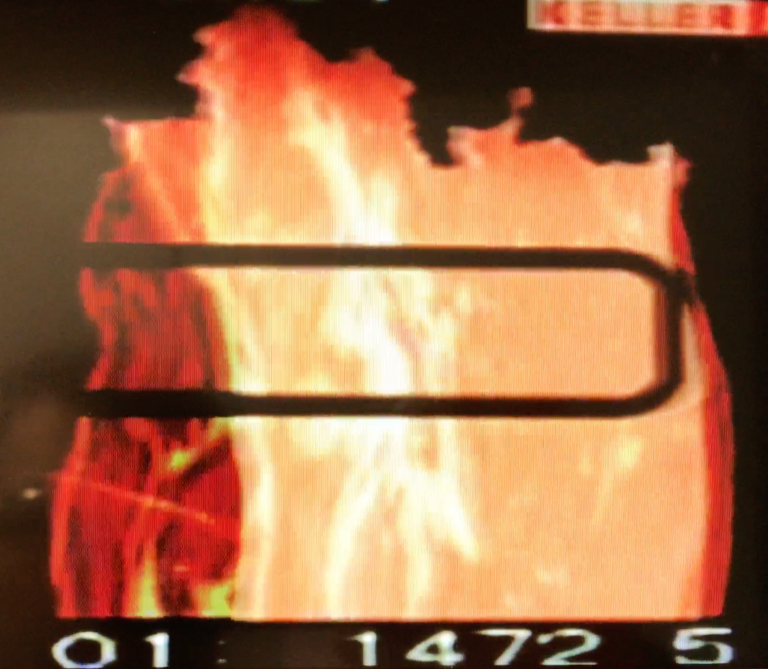

Temperature monitoring - Pyrometer

For verifiable pouring temperatures

The Pyrometer measures temperature in the pouring stream and displays the temperature of each single mold. It has a special pouring stream mode to calculate one average temperature value for each single pour. Temperature values in the beginning and the end of the casting process can be eliminated which can affect the correct measurement. The shape of the optics’ focus point is a line, which guarantees that even a moving pouring stream is always within the spot. The pyrometer is equipped with a lens contamination monitoring system. A low signal strength is caused by contamination of the lens or a sighting window, a signal output switches an alarm transmitter.

- Molten metal has a very low and fluctuating emissivity.

- The pouring stream moves, which will be compensated by the pyrometer.

The pouring stream temperature of each single pour, that means each single poured part, can be recorded. The temperature value of each finished pour is displayed on the pyrometer and all analogue and digital outputs. The measured values are displayed in the pourTECH™ HMI and can be stored in the database.

In order to have a reliable measurement, the system must be calibrated with a dip lance measurement system. The lance will be integrated in the pourTECH™ system as well. The calibration process for the emissivity will be done automatically by the pourTECH™ system.

The pyormeter is constructed for all bottom pouring systems like the unheated bottom pouring ladle working with horizontal and vertical mold lines.

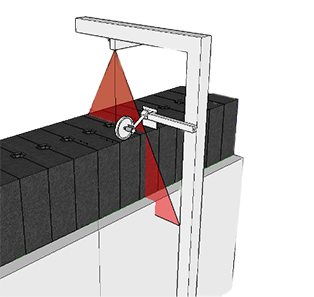

FORCEpour™

Cycle time saving and productivity increase

To increase productivity on vertical molding lines, we have developed a function for pre-opening of the stopper rod in order to gain valuable time from the production cycle and increase the productivity. At the start of the mold line index, the pourTECH™ system calculates the new pouring location, based on feedback from the mold line, and moves the pouring vessel to that position (if necessary).

As the mold is approaching its final position, the pourTECH™ system will begin the pour – while the mold is still moving but timed such that the mold just arrives to receive the first iron instead of pouring on top of the mold. At the end of the index, the pouring sensor will verify the cup location, and the vessel position will be adjusted (if necessary).

The FORCEpour™ feature is integrated into the pourTECH™ control system and can provide cycle time savings from 0.5 to 1 seconds (depending on the mold line) equaling production increases of up to 15%.

FORCEpour™ requires a proportional positioning system to continually position the pouring vessel. It is available for pourTECH™ systems equipped with 3D LindaLlaser™ or Single Point laser sensors.

The FORCEpour™ is constructed for all bottom pouring systems like the unheated bottom pouring ladle working with horizontal and vertical mold lines.

Ofensteuerung

The connection to the pouring Furnace

The pourTECH™ system has built in functionality for control of pouring furnace. The operation of the pouring furnace is integrated into the pourTECH™ system, using the same operator panel HMI as the rest of the system. Parameters such as switching times etc. are entered into a special furnace screen. The same screen is used for visualization of any information given by the furnace hardware, such as voltage, current, power, phase-angle, resistance and reactance.

The system can be operated in manual, automatic and superheat mode. A special mode called sintering mode can be used during sintering of a new inductor.

The furnace control within pourTECH™ Systems is always combined with a hardware backup solution to prevent any freezing of the inductor.

PT - Database

following up with Industry 4.0

Intention of PT-Database is storing data and providing the possibility of tracking the pouring performance.

Base option enables CODESYS to store data in a SQL database. The recommended choice is saving the data on an additional computer with two Raid Hard disks installed in the main cabinet. This ensures that all data is stored, and no data is lost. The storing software for data in the database can send data to remote SQL Databases.

Important information will be provided by the database. For example, all operator changes are tracked and available for training. With each pour, various pictures from pouring and inoculation are taken. Analysing all provided information can lead to a quality and productivity improvement.

A web-based tool to monitor in real-time the performance of the pourTECH™. Web applications can be used on any computer or smartphone with a browser. The creation of tailormade custom reports on the performance over a certain period of time can be created independently.

PT – Database is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

The automatic pourTECH™ system is equipped with an electric servo drive stopper rod actuator unit, hydraulic, pneumatic, hardware and control systems.

The system operates on horizontal and vertical mold lines, and will perform as follows:

- The PLC controls the flow of molten metal from the nozzle into the mold by opening and closing the stopper. It gets information by the laser to be able to adjust the filling speed. Using the specific parameter stored in a database, the pouring will be performed for each individual pattern.

- A communication with the mold line assures the correct pouring parameter for each mold.

- Operator is released from the basic setup of the pouring. Only adjustements are needed.

- The PLC will position the pouring unit with the nozzle over the pouring cup by a dedicated laser control system.

In case of Mg-treated iron a pneumatic driven stopper twist and plunger can be supplied.

Profit from automatic pouring

Qualitätssteigerung

By having constant pouring conditions the quality will be improved and the scrap rate can be reduced.

profitable production

Higher output of the foundry due to higher yield.

possibility to upgrade

For a higher level of automation the system is designed to accommodate additional needed sensors and equipment.

relief for the operator

Operators are released from the repeatable work. They can do some other work during the pouring, like temperature measurement and deslagging.

constant pouring time

That means the influence of quality issues by inconstant pouring time can be reduced.

3D line laser™ technology

Improvement of yield by reduction of pouring cup size

The 3D laser™ system consists of C-MOS receiver, Line Laser and Positioning Laser. The Line laser generator and 3D sensor are positioned on opposing sides. The laser projects a laser line across the top of the mold. From the opposing side, the C-Mos receiver determines the profile and elevation of the line. The 3-D Laser system finds the pouring cup and then provides real-time metal level feedback to the control system.

- Housed in stainless-steel water-cooled jackets

- Self-contained with closed loop cooling system for optimum operating temperature

- Keeps dirt away from sensor optics by air purge for positive pressure inside

The 3D laser™ is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines. The pouring cup size can be reduced to a minimum and leeds to an elimination of the “laser tail”.

Single point laser

For pouring solutions with limited space

The Single Point Laser projects a laser dot at the top of the mold. By triangulation principle, the measurement of the level will be performed. The Laser system finds the pouring cup and then provides real-time iron level feedback from the tail to the control system.

- Pouring cup needs the “laser tail”

- Stable measurement and high reliability

- Housed in stainless-steel water-cooled jackets

- Self-contained with closed loop cooling system for optimum operating temperature

- Keeps dirt away from sensor optics by air purge for positive pressure inside

The Single Point Laser is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

vision technology

For vertical mold lines

with large pouring cups

The video camera is focused on the pouring cup observing the iron level to adjust a constant level while pouring. The sand mold in the back of the iron stream gives the contrast for the camera, no additional or special lighting is required.

The information about the pouring process will send pixel information to the PLC processor for counting the illuminated pixels for calculation of the cup filling.

- Housed in stainless-steel water-cooled jackets

- Self-contained with closed loop cooling system for optimum operating temperature

- Keeps dirt away from sensor optics by air purge for positive pressure inside

The vision technology is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

Automatic in-stream inoculation

for a reliable and real-time inoculation before solidification

The 3D laser™ is constructed for ??? working with horizontal and vertical mold lines. For the pouring process the in-stream inoculation is a significant requirement for the casting quality.

Our inoculations unit are known for:

- high uptime

- having multiple sensors for reliable operation

- being easy to install

- being easy to calibrate

- the skill to operate with double feeder system with different inoculants The in-stream inoculation is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

The in-stream inoculation is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

The Inoculation unit works with removable hoppers for capacities of 25 or 50 kg, powder grain size of 0.8 mm and density of approx. 1.7 kg/dm3. Feeding rates between 1 – 80 gram/sec are available. The amount of delivered inoculant can be recorded in the database. The HMI screen shows all the significant status information.

The dosing unit also provides automatic error checking, using a variety of sensors to check for:

- Low level in the hopper

- No (insufficient) air supply

- Feeder screw operation

- No inoculation is fed

- Incorrect feed rate

- Incorrect injection pressure

- Blocked inoculation pipe

The in-stream inoculation control is integrated into the pourTECH™ automatic pouring control system for full control over the inoculation unit. pourTECH™ makes it possible to individualize the inoculation rate for each job. By controlling the timing of the inoculation signal, it can ensure that the first inoculants reach the pour cup together with the iron so that the entire casting is inoculated.

In addition, the pourTECH™ system monitors all alarms and can provide a quality record for every casting.

The integrated control system allows easy calibration of the feed rate and various monitoring functions and is designed for reliable operation

Automatic positioning

By use of 3D Line or Spot Laser the system will perform the Automatic Positioning without the need of installing other equipment. When the cup is detected, the pouring unit will be moved to the correct pouring position.

- An encoder tracks all sand/mold line movements, completely separate from all other systems.

- The sensor is programmed to identify pouring cups.

- The sensor detects the cup while it passes by the scanner and stores its position.

- All cups are analyzed individually for dimension, position and any other possible differences.

The 3D laser™ is constructed for ??? working with horizontal and vertical mold lines.

Temperature monitoring - Pyrometer

For verifiable pouring temperatures

The Pyrometer measures temperature in the pouring stream and displays the temperature of each single mold. It has a special pouring stream mode to calculate one average temperature value for each single pour. Temperature values in the beginning and the end of the casting process can be eliminated which can affect the correct measurement.

The shape of the optics’ focus point is a line, which guarantees that even a moving pouring stream is always within the spot. The Pyrometer is equipped with a lens contamination monitoring system. A low signal strength is caused by contamination of the lens or a sighting window, a signal output switches an alarm transmitter.

The pyormeter is constructed for all bottom pouring systems like the unheated bottom pouring ladle working with horizontal and vertical mold lines.

- Molten metal has a very low and fluctuating emissivity.

- The pouring stream moves, which will be compensated by the Pyrometer.

The pouring stream temperature of each single pour, that means each single poured part, can be recorded. The temperature value of each finished pour is displayed on the Pyrometer and all analogue and digital outputs. The measured values are displayed in the pourTECH™ HMI and can be stored in the database.

In order to have a reliable measurement, the system must be calibrated with a dip lance measurement system. The lance will be integrated in the pourTECH™ system as well. The calibration process for the emissivity will be done automatically by the pourTECH™ system.

FORCEpour™

Cycle time saving and productivity increase

To increase productivity on vertical molding lines, we have developed a function for pre-opening of the stopper rod in order to gain valuable time from the production cycle and increase the productivity.

At the start of the mold line index, the pourTECH™ system calculates the new pouring location, based on feedback from the mold line, and moves the pouring vessel to that position (if necessary).

FORCEpour™ is constructed for all bottom pouring systems like the unheated bottom pouring ladle working with horizontal and vertical mold lines.

As the mold is approaching its final position, the pourTECH™ system will begin the pour – while the mold is still moving but timed such that the mold just arrives to receive the first iron instead of pouring on top of the mold. At the end of the index, the pouring sensor will verify the cup location, and the vessel position will be adjusted (if necessary).

The FORCEpour™ feature is integrated into the pourTECH™ control system and can provide cycle time savings from 0.5 to 1 seconds (depending on the mold line) equaling production increases of up to 15%.

FORCEpour™ requires a proportional positioning system to continually position the pouring vessel. It is available for pourTECH™ systems equipped with 3D Line Laser™ or Single Point Laser sensors.

Ofensteuerung

The connection to the pouring furnace

The pourTECH™ system has built in functionality for control of pouring furnace. The operation of the pouring furnace is integrated into the pourTECH™ system, using the same operator panel HMI as the rest of the system. Parameters such as switching times etc. are entered into a special furnace screen. The same screen is used for visualization of any information given by the furnace hardware, such as voltage, current, power, phase-angle, resistance and reactance.

The system can be operated in manual, automatic and superheat mode. A special mode called sintering mode can be used during sintering of a new inductor.

The furnace control within pourTECH™ Systems is always combined with a hardware backup solution to prevent any freezing of the inductor.

PT - Database

Intention of PT-Database is storing data and providing the possibility of tracking the pouring performance.

Base option enables CODESYS to store data in a SQL database. The recommended choice is saving the data on an additional computer with two Raid Hard disks installed in the main cabinet. This ensures that all data is stored, and no data is lost. The storing software for data in the database can send data to remote SQL Databases.

PT – Database is constructed for all bottom pouring systems like the unheated bottom pouring ladle and pouring furnaces working with horizontal and vertical mold lines.

QUALITY AND PRODUCTIVITY IMPROVEMENT

Important information will be provided by the database. For example, all operator changes are tracked and available for training. With each pour, various pictures from pouring and inoculation are taken. Analysing all provided information can lead to a quality and productivity improvement.

A web-based tool to monitor in real-time the performance of the pourTECH™. Web applications can be used on any computer or smartphone with a browser. The creation of tailormade custom reports on the performance over a certain period of time can be created independently.