About

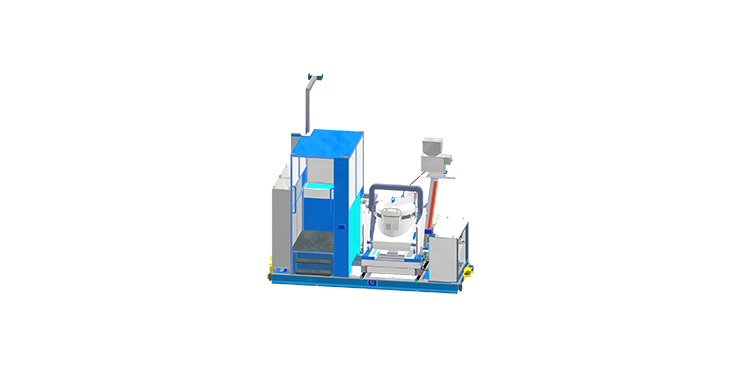

A saver production with increased speed: In addition to bottom pouring ladles and furnaces, we offer a much simpler tilt pouring system, which is perfect for pouring small batches on flask lines. Especially if the metal grade changes frequently, the tilt pouring system is the most convenient solution.

- Capacity: 1.000 – 5.000 kg

- Travel speed 100mm/sec.

- Hydraulic tilting

Perfect solution for you?

For a profitable and efficient use of the tilt pouring use case, individual requirements and production properties play a decisive role. The criteria listed below provide a rough guide to check if thi ssystem is the optimal solution for you. Please note that these criteria are weighted on a case-by-case basis – we are happy to advise you on this.

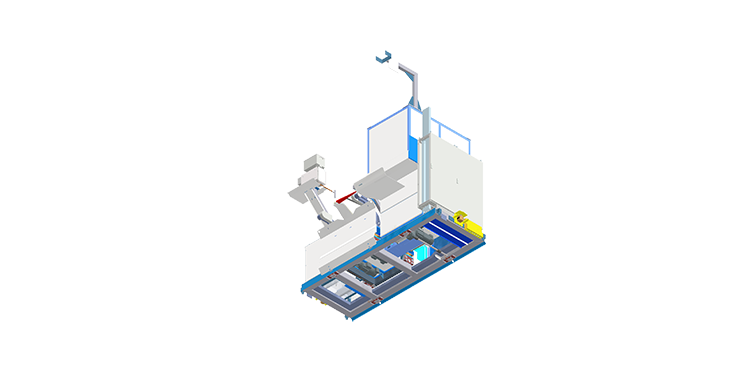

Operator Cabin on the carriage

- For optimal pouring conditions

- Keeps the operator safe from iron

- Main functions controllable from the carriage

Easy Pouring

- Precise hydraulic tilting

- Pivot point in the center of pouring stream

Covered Ladles

- Reduce temperature losses

- Keep the operators away from heat radiation

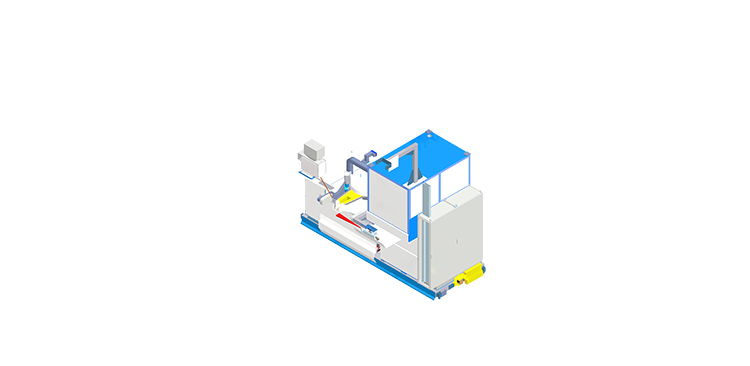

Long and Crosstravel

- Carriage can move along the moldline

- Pouring position can change for different models

- Pouring stream can be adjusted to hit the mold at exactly the right spot

Modline Synchronisation

- Carriage can be synchronised to the moldline movements

- Pouring can continue during indexing of the moldline

Safety

- Equipped with sensors scanning the surroundings

- People are safe to walk around the carriage without the danger of getting hit

Not the right product?

View other products or contact us. We also customize products for various use cases!

A saver production with increased spped: In addition to bottom pouring ladles and furnaces, we offer a much simpler tilt pouring system, which is perfect for pouring small batches on flask lines. Especially if the metal grade changes frequently, the tilt pouring system is the most convenient solution.

TECHNICAL INFORMATION

- Capacity: 1.000 – 5.000 kg

- Travel speed 100mm/sec.

- Hydraulic tilting

Perfect solution for you?

For a profitable and efficient use of the tilt pouring use case, individual requirements and production properties play a decisive role. The criteria listed below provide a rough guide to check if thi ssystem is the optimal solution for you. Please note that these criteria are weighted on a case-by-case basis – we are happy to advise you on this.

Operator Cabin on the carriage

- For optimal pouring conditions

- Keeps the operator safe from iron

- Main functions controllable from the carriage

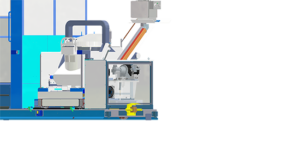

Easy Pouring

- Precise hydraulic tilting

- Pivot point in the center of pouring stream

Covered Ladles

- Reduce temperature losses

- Keep the operators away from heat radiation

Long and Crosstravel

- Carriage can move along the moldline

- Pouring position can change for different models

- Pouring stream can be adjusted to hit the mold at exactly the right spot

Modline Synchronisation

- Carriage can be synchronised to the moldline movements

- Pouring can continue during indexing of the moldline

Safety

- Equipped with sensors scanning the surroundings

- People are safe to walk around the carriage without the danger of getting hit

Not the right Product?

View other products or contact us. We also customize products for various use cases!