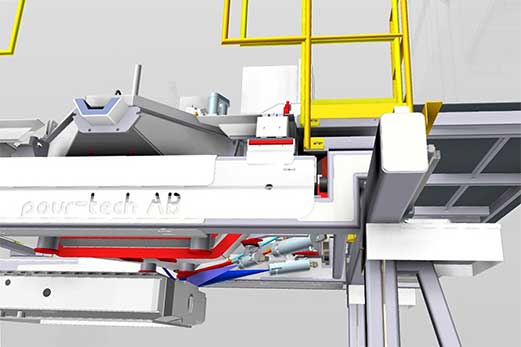

Automatic pouring system

Automatic pouring system

Pour gray iron, ductile iron, CGI, High Chrome and other irons on horizontal and vertical molding systems with ease.

Thanks to the intuitive HMI, the foundry employees can quickly and easily adjust casting parameters and operate the system.

Each system will be individually adapted to your requirements, specially designed, and manufactured for your production.

We are at your disposal in every phase of the project – from purchase order to after sales support. After the individual technical advice, we can take over the planning and installation, if required.

We are combining Swedish know-how and ingenuity with world renown German machine building tradition.

From Europe to Africa, Asia and the Americas. Our systems are available around the globe.

Together we evaluate the most cost-effective solution for you: Can your existing system be upgraded or should it be replaced by a new system?

Equipped with the latest hard- and software as well as artificial intelligence, our systems provide State of the Art solutions thanks to constant research and development.

Pour gray iron, ductile iron, CGI, High Chrome and other irons on horizontal and vertical molding systems with ease.

Thanks to the intuitive HMI, the foundry employees can quickly and easily adjust casting parameters and operate the system.

Each system will be individually adapted to your requirements, specially designed, and manufactured for your production.

We are at your disposal in every phase of the project – from purchase order to after sales support. After the individual technical advice, we can take over the planning and installation, if required.

We are combining Swedish know-how and ingenuity with world renown German machine building tradition.

From Europe to Africa, Asia and the Americas. Our systems are available around the globe.

Together we evaluate the most cost-effective solution for you: Can your existing system be upgraded or should it be replaced by a new system?

Equipped with the latest hard- and software as well as artificial intelligence, our systems provide State of the Art solutions thanks to constant research and development.

Working with experts

As market-leader in automatic pouring we help you to reduce costs and increase the effectivity of your iron foundry due to latest technologies and I/O standards.

We offer you the perfectly adapted (automated) product, superior service, extensive advice, and constant further development. Therefore, we have put together a worldwide team of more than 30 experts, including foundry experts, laser vision engineers and software developers.

- staff with more than 25 years of experience

- competent team of engineers and software developers

- focus on customer value

- individual consultation

- fast reaction time

Working with experts

- staff with more than 25 years of experience

- competent team of engineers and software developers

- focus on customer value

- individual consultation

- fast reaction time

get the service you need

Individual construction for every Use Case.

Shortly after your placed order, spare parts will be shipped out from our headquarter in Sweden or our partner office in the US.

Thanks to our updates, your system will always be State of the Art.

The maintenance and repair work is handled remote or on site at the foundry.

To get the most out of your system, the operators and maintenance staff will be trained by our experts.

get the service you need

The Perfect pouring System

for your production

Labor shortage, overflows, short and interrupted pours, incorrect casting temperatures and other important parameters cause challenges in the casting process. The use of our systems prevents this through automation and the job of a pouring operator becomes more desirable.

The correct movement of the stopper and perfectly evaluated casting parameters together with the real-time measurements by laser and camera ensures an almost perfect casting result for every casting, which leads to profitable long-term effects for your foundry.

The correct movement of the stopper and perfectly evaluated casting parameters together with the real-time measurements by laser and camera ensures an almost perfect casting result for every casting, which leads to profitable long-term effects for your foundry.

quality improvement

Do your customers place higher quality demands on you? Up tp 30% increased casting quality as well as a flawless end product.

cost reduction

Reduced re-melt, casting process and consumable costs such as inoculants, circulation material, nitrogen, and the efficient use of employees in other areas reduce around 50% of costs.

less defect castings

Increase customer satisfaction thanks to fewer faulty castings that are prevented by individual casting dependent parameters.

work relief

By removing employees out of the dangerous pouring area, there is an enormous advantage in terms of work quality in addition to the occupational safety aspect: employees can be deployed more efficiently in other places in your foundry.

time saving

Time is money - and so much more. Benefit throughout your production from faster casting times, fewer errors, more cast parts per hour and shorter downtimes in the casting process.

sustainable

A sustainable improvement in production. In addition to reduced Co2 emissions due to lower power consumption and savings in recycled materials, financial sustainability plays a major role.

The Perfect pouring System

for your production

The correct movement of the stopper and perfectly evaluated casting parameters together with the real-time measurements by laser and camera ensures an almost perfect casting result for every casting, which leads to profitable long-term effects for your foundry.

reducing costs

Reduced re-melt, casting process and consumable costs such as inoculants, circulation material, nitrogen, and the efficient use of employees in other areas save around 30% of costs.

quality improvement

Do your customers place higher quality demands on you? 50% increased casting quality as well as a flawless end product.

Less Defect Castings

Increase customer satisfaction thanks to fewer faulty castings that are prevented by individual casting dependent parameters.

Intelligent pouring with EASYpour™

Meet EASYpour™ – a system that enables a very high consistency in your production and takes full advantage of every piece of equipment.

It is complicated getting skilled operators for one of the most important process in the foundry – pouring the molds. Therefore, we have developed a digital operator supported by artificial intelligence. Based on self-learning algorithms the system controls the pouring parameters to consciously optimize the pouring, aiming to maintain a high and consistent pouring result.

STAY infoRmed

STAY infoRmED

STAY TUNED

Sign up now for our newsletter and receive exclusive insights, exciting offers, and relevant information delivered straight to your inbox.

STAY TUNED

Sign up now for our newsletter and receive exclusive insights, exciting offers, and relevant information delivered straight to your inbox.