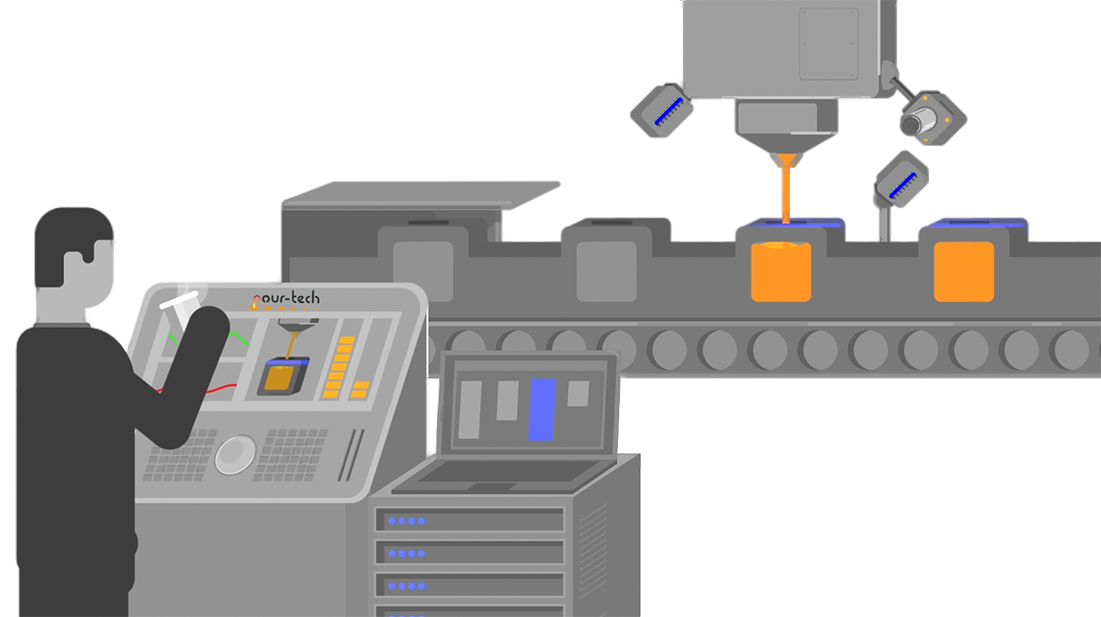

Anode Pouring System

specifically designed for primary aluminium smelters

Laser-guided accuracy

PRECISE FILLING

Consistent results through real-time level monitoring for each anode

Furnace integration

TEMPERATURE STABILITY

Pouring directly from the furnace ensures minimal thermal loss

Expandable system

MODULARITY

Optional charging vehicle and other features available on request

System Highlights

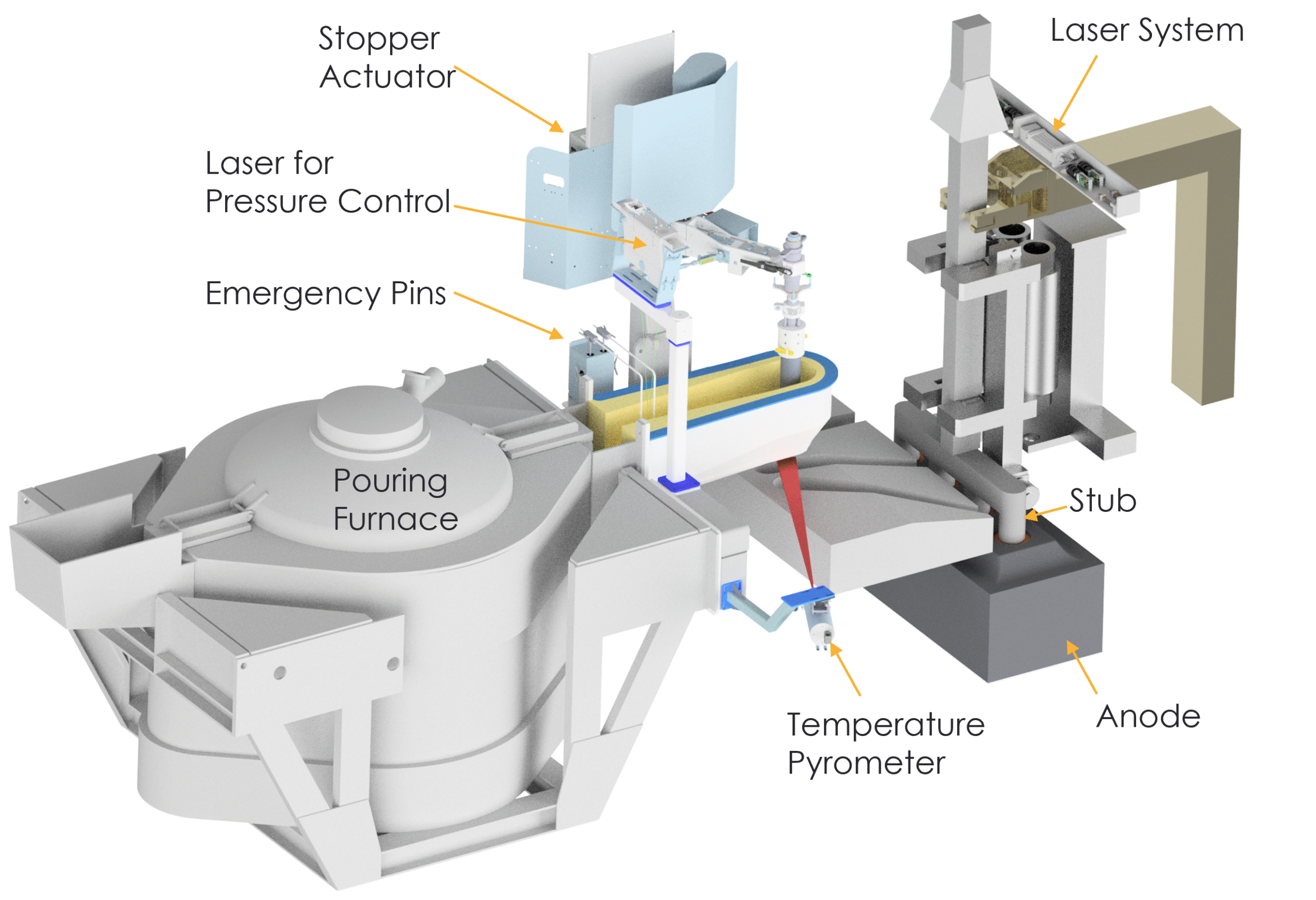

Anode pouring presents a set of unique challenges: high pouring temperatures, variations in stub position and geometry, fluctuating iron levels, and humidity in the anodes. These factors can affect filling consistency and the quality of the anode-to-stub connection.

pour-tech AB offers a reliable and highly controlled anode pouring system, specifically designed for primary aluminium smelters. The system ensures consistent and repeatable results – even under harsh operating conditions.

- Stopper-Based Pouring

A precise metal flow is achieved using stopper technology, reducing turbulence and ensuring clean filling in the stub hole.

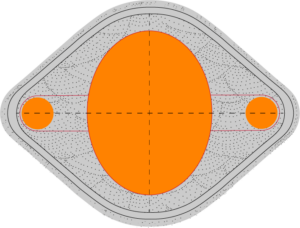

- Laser Level Control

Each anode is monitored individually via laser-based level measurement to maintain a consistent fill height, regardless of stub differences.

- Stub-Specific Laser Monitoring

Lasers positioned above each anode continuously monitor position, filling status, and surface behavior in real time.

- Integrated Furnace Control

Pouring directly from the furnace under consistent iron conditions ensures temperature stability and process reliability.

- Iron Buffer Capacity

A larger molten iron buffer stabilizes the pouring process and minimizes temperature fluctuations during batch transitions.

perfect solution for you?

For a profitable and efficient use of the coreless automatic pouring furnace the use case, individual requirements and production properties play a decisive role. The criteria listed below provide a rough guide to check if this system is the optimal solution for you. Please note that these criteria are weighted on a case-by-case basis.

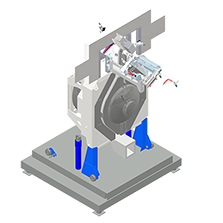

Explore the Anode Pouring System in 3D

This interactive 3D model showcases the core elements of pour-tech’s anode pouring system – including the stopper mechanism, laser measurement setup, and furnace connection. It demonstrates how process stability, precision, and efficiency are achieved in demanding smelting environments.

Note:

This model does not represent the full system configuration. Optional components – such as a semi-automated charging vehicle – and many other features can be integrated based on customer-specific requirements.

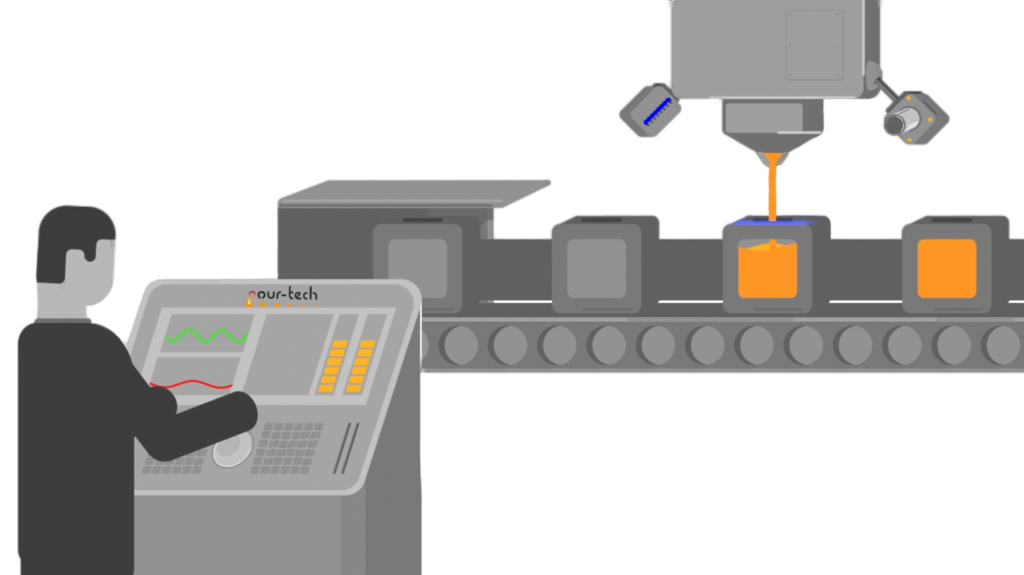

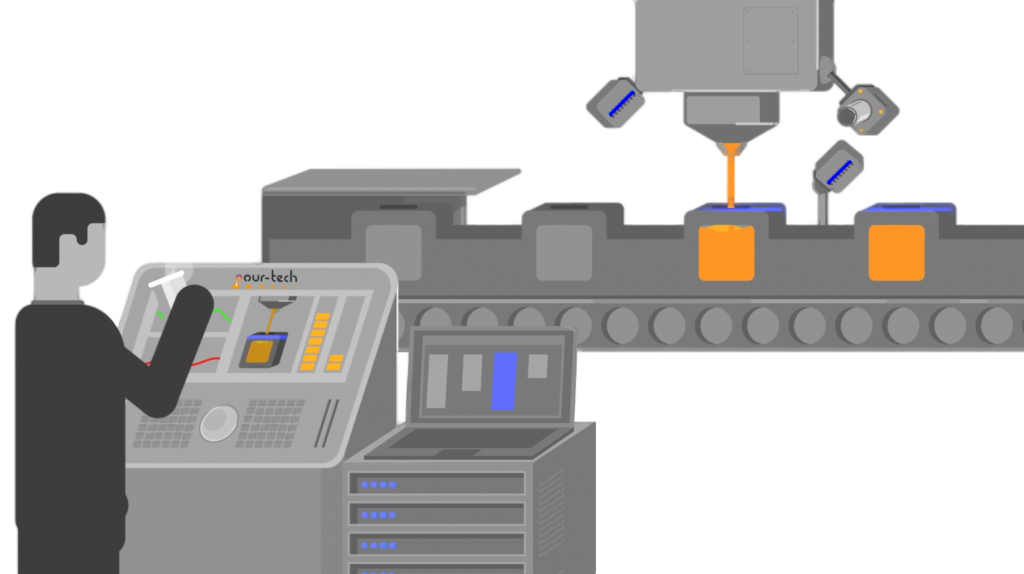

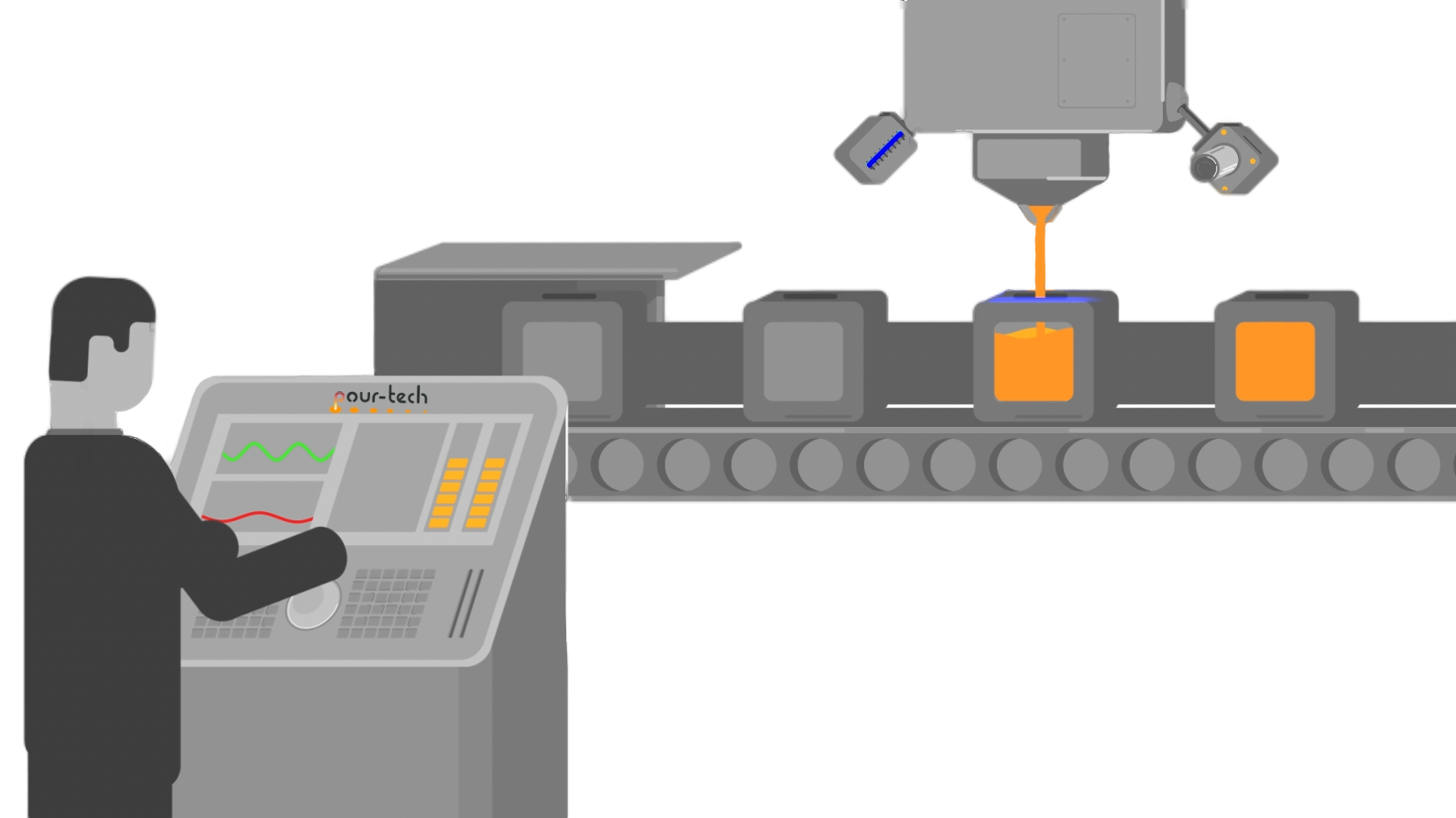

Upgrade to automation

Each of our products is designed to be equipped with software, lasers and cameras on request. Upgrade the system to speed up pouring process and work steps to a large extent with less effort at the same time. When talking about automatic pouring, we distinguish between three levels that build on one another.

The coreless pouring furncae can be easily upgraded at any time in order to start with a simple manual system and convert it to a sophisticated, automated system. By adding special features, it may be possible to significantly increase the production output while reducing the manpower to do it.

Not the right product?

View other products or contact us. We also customize products for various use cases!

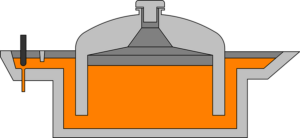

Together with our partner CIME S.r.l. (Crescenzi Induction Melting), we supply coreless induction pouring furnaces in combination with our stopper pouring control. There are more than 150 CIME pouring furnaces installed in countries all over the world at the moment. Thanks to their patented design they can be used for all metal grades and is well suited for mixed production.

TECHNICAL INFORMATION

- Capacity: 1.500 kg – 25.000 kg

- Power: 200 – 1.000 kg

- Power Efficiency: 0,9 – 1

- Overheating up to 100 K/min

perfect solution for you?

For a profitable and efficient use of the coreless pouring furnace the use case, individual requirements and production properties play a decisive role. The criteria listed below provide a rough guide to check if this system is the optimal solution for you. Please note that these criteria are weighted on a case-by-case basis.

Coil made from interchangeable sections

- Each section with its own cooling, temperature control, and visualiuation on HMI

- Each section bridgeable in case of damage, no need to stop production because of damaged coil

- Each section interchangeable during maintenance

- No brazed joints that could fail

Empty 100%

- Rapid change of alloy

- Turn off power for longer stops

- Easy cleaning

Siphons inside the coil

- Constant temperature in the ducts

- More precise pouring temperature

- Siphons are easy to clean (possible to overheat for de-slagging)

Possibility to remelt

- No need to destroy the lining after power outage

Possibility to use nitrogen

- Less magnesium fading in ductile iron

Upgrade to Automation

These are available either as manual or (semi-) automated or intelligent solution. The system can be easily upgraded at any time to obtain a sophisticated system.

When talking about automatic pouring, we distinguish between three levels that build on one another. Upgrade the Coreless Pouring Furnace to speed up pouring process and work steps to a large extent with less effort at the same time.

Semi-automatic pouring

For a solid and constant pouring process in your production.

Automatic pouring

Pouring upgrade leading to a fast, independent and accurate process.

Intelligent pouring

The high-end solution for an intelligent and a self-learning production.

Not the right Product?

View other products or contact us. We also customize products for various use cases!