Unheated Bottom Pouring Ladle

high flexibility With LOW COST

Suitable for all

METAL GRADES

high level of

automation

can be equipped with a wide variety of equipment bring automation to a superior level

fits every

MOLD LINE

tailormade to suit your requirements, bringing automation to places previously not thought of

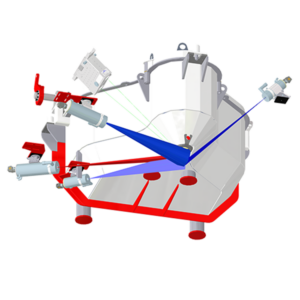

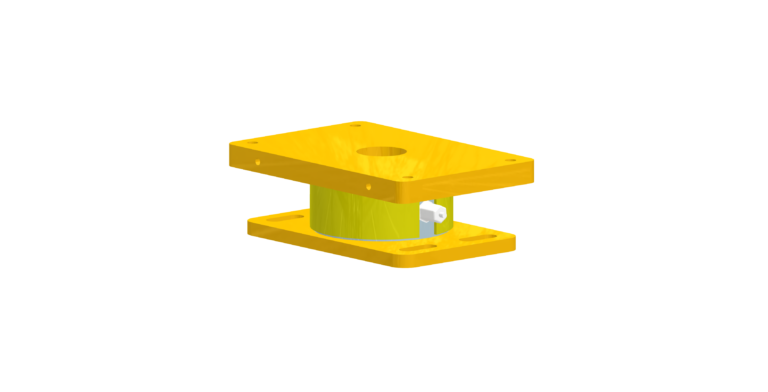

Unheated bottom Pouring Ladle System – made in Germany

The outstanding unheated bottom pouring ladle was made for foundries producing a wide range of iron grades with high demands on flexibility and quality. It is designed for fast iron grade changes and offers reduced temperature and fading losses. It can be equipped with a wide variation of auxiliary equipment to bring automation to a superior level. Starting from a basic design, the pouring systems are tailormade to fit any mold line – typically producing 60 to 600 molds per hour.

MAS Metallverarbeitung GmbH has been our partner for steelworks and construction since 2011. Together, we build and develop all our eupiment, including the unheated bottom pouring ladles, at our location in Kitzingen, Germany. Thanks to the know-how gatherd over the years, the experience and the flawless construction, all systems meet the highest quality requirements in order to offer you the best and most flexible solution for your foundry.

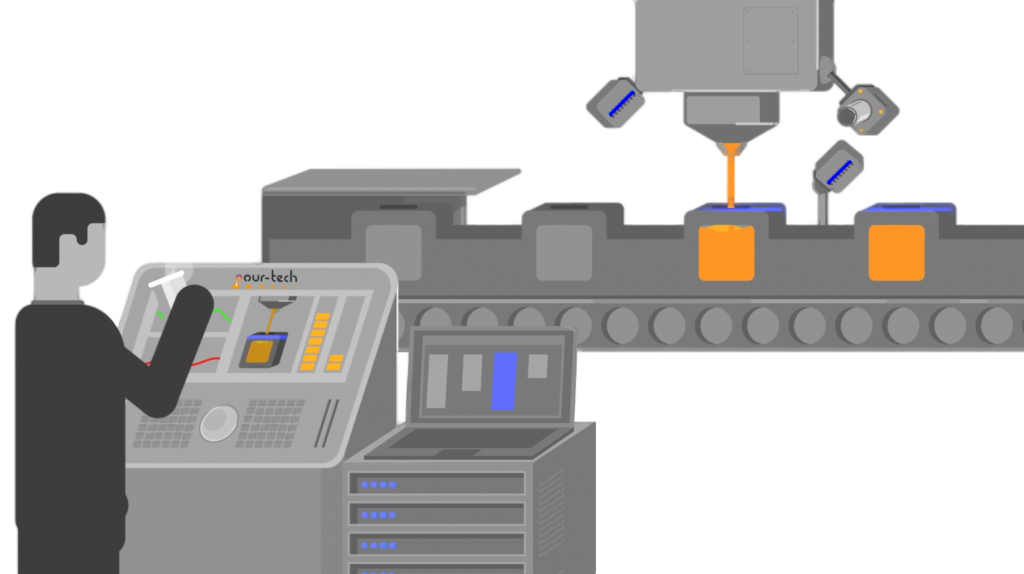

For ductile and other iron grades, the actuator can be equipped with a plunger system that functions as a nozzle cleaner, keeping the nozzle free from slag. The automatic pouring system is available with a variety of sensors for real-time measurement of the metal level in the pour cup – including the sophisticated Line Laser system. For closed-loop performance feedback, a secondary laser can be added for measuring the final level in the pour cup – allowing the pouring controls to make automatic parameter adjustments. The pourTECH DataBase (PTDB) is available for storing production infortion for years – allowing the user to go back and investigate the system performance, operator setting and equipment status when a specific mold was poured.

Starting from a basic design, the pouring systems are tailormade to fit any molding line – typically producing 60 to 600 molds per hour.

| PL1.8 | PL2.8 | PL4.0 | PL5.0 | |

| Nominal Capacity (kg)* | 1.000 – 1.800 | 2.000 – 2.800 | 3.000 – 4.000 | 4.000 – 5.000 |

| Heal (kg) | 350 | 500 | 600 | 1.000 |

| Charging ladle (kg) | 600 – 1.200 | 1.200 – 2.000 | 2.000 – 3.000 | 3.000 – 3.500 |

| Production capacity (t/h)* | 3.3 – 9.5 | 8.5 – 16 | 11 – 23 | 15 – 28 |

| Temperature Losses (min) | 1 – 3 K under stable production conditions | |||

| * by using different lining formers | ||||

We provide suitable transfer ladles featuring capacities from 500 to 4.000kg.

Perfect solution for you?

For a profitable and efficient use of the unheated bottom pouring ladle the use case, individual requirements and production properties play a decisive role. The criteria listed below provide a rough guide to check if this system is the optimal solution for you. Please note that these criteria are weighted on a case-by-case basis.

Fully Automatic Pouring or Manual Pouring

Continuous operation

- Designed to be refilled every 7-10 min

- Minimizing of temperature loss and magnesium fading

- Can be emptied for longer stops

- Can be heated by burner

Load Cells

- Equipped with pancake load cells to measure weight

- Automatic compensation for ferrostatic pressure variations

- Operators can keep track of remaining iron without opening the lid, loosing temperature

- Weight can be shown on remote location (e.g. melt shop)

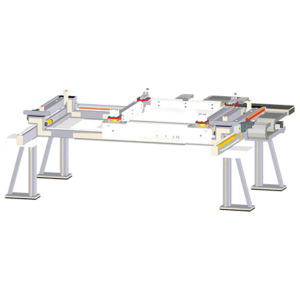

Frame Stand and Carriage

- Mounted to a series of frames

- Can travel in every direction (even height changes can be realized)

- Can backtilt

- Only top frame needs to be on load cells to rule out weight measurement errors

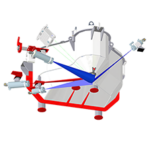

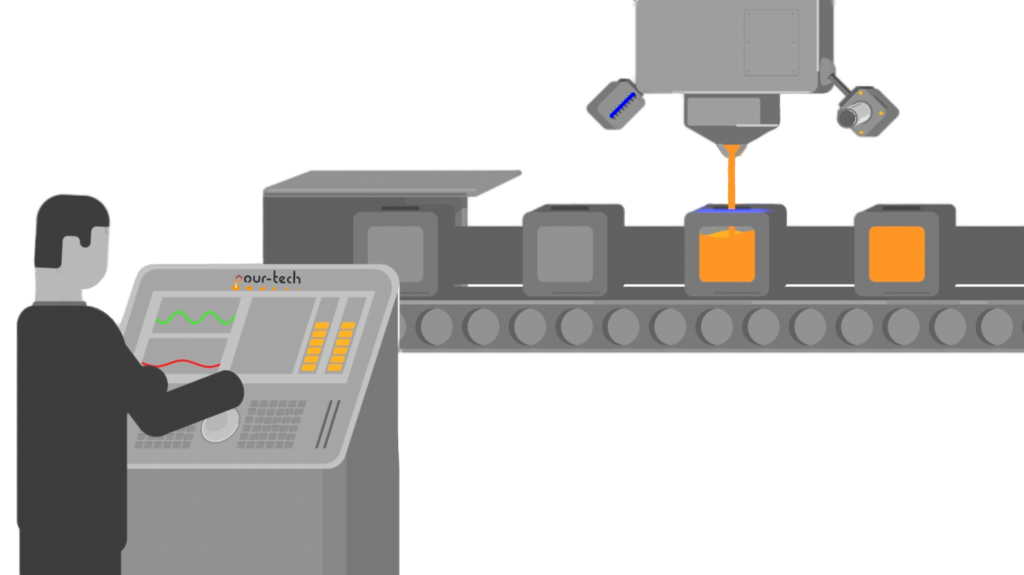

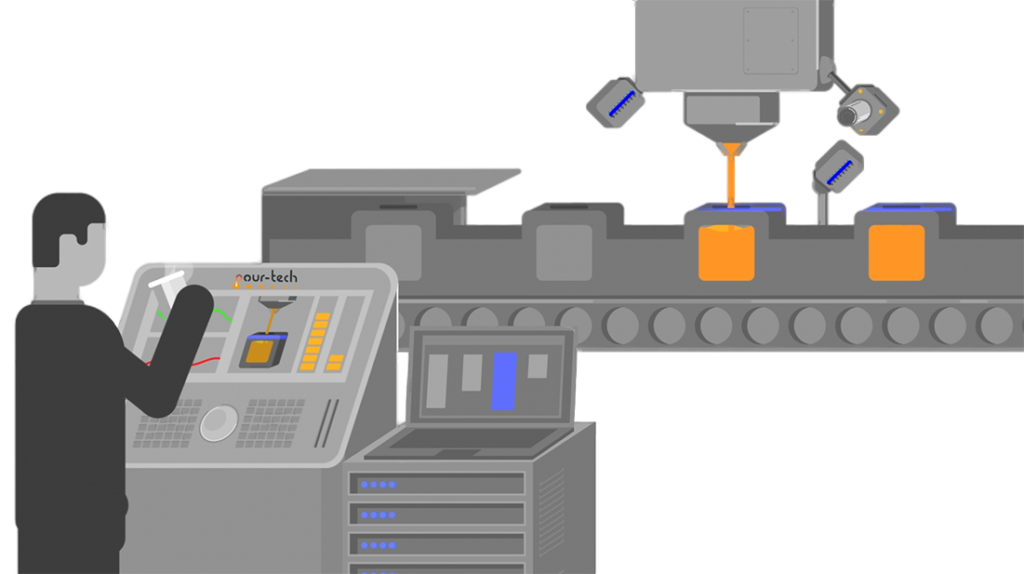

Upgrade to automation

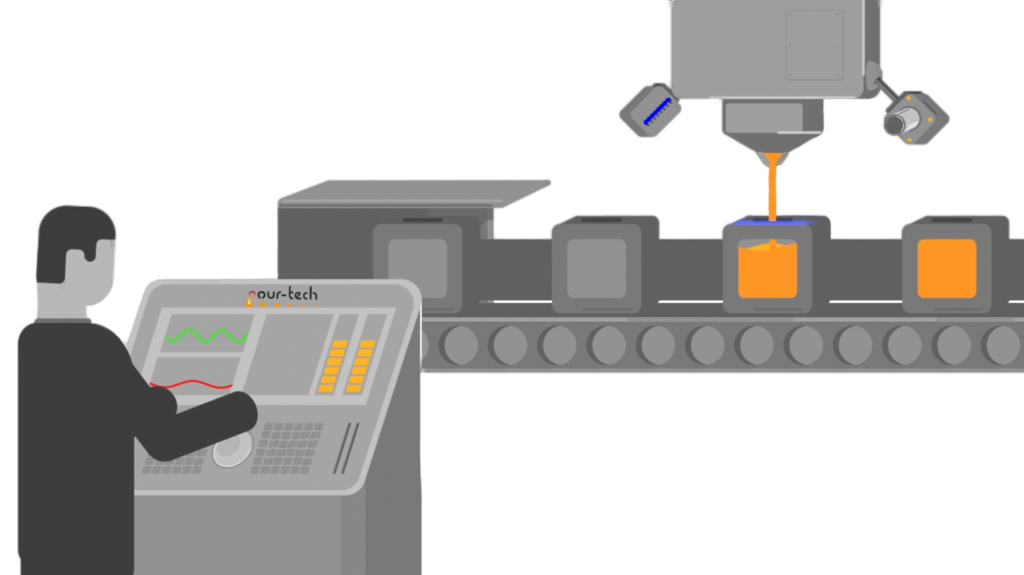

Each of our products is designed to be equipped with software, lasers and cameras on request. Upgrade the system to speed up pouring process and work steps to a large extent with less effort at the same time. When talking about automatic pouring, we distinguish between three levels that build on one another.

The unheated stopper pouring ladle can be easily upgraded at any time in order to start with a simple manual system and convert it to a sophisticated, automated system. By adding special features, it may be possible to significantly increase the production output while reducing the manpower to do it.

Not the right product?

View other products or contact us. We also customize products for various use cases!

The outstanding unheated bottom pouring ladle was made for foundries producing a wide range of iron grades with high demands on flexibility and quality. It is designed for fast iron grade changes and offers reduced temperature and fading losses. It can be equipped with a wide variation of auxiliary equipment to bring automation to a superior level. Starting from a basic design, the pouring systems are tailormade to fit any mold line – typically producing 60 to 600 molds per hour.

MAS Metallverarbeitung GmbH has been our partner for steelworks and construction since 2011. Together, we build and develop all our eupiment, including the unheated bottom pouring ladles, at our location in Kitzingen, Germany. Thanks to the know-how gatherd over the years, the experience and the flawless construction, all systems meet the highest quality requirements in order to offer you the best and most flexible solution for your foundry.

For ductile and other iron grades, the actuator can be equipped with a plunger system that functions as a nozzle cleaner, keeping the nozzle free from slag. The automatic pouring system is available with a variety of sensors for real-time measurement of the metal level in the pour cup – including the sophisticated Line Laser system. For closed-loop performance feedback, a secondary laser can be added for measuring the final level in the pour cup – allowing the pouring controls to make automatic parameter adjustments. The pourTECH DataBase (PTDB) is available for storing production infortion for years – allowing the user to go back and investigate the system performance, operator setting and equipment status when a specific mold was poured.

- Capacity: 1.000-5.000kg

- Production Capacity: 3.3-38 t/h

- Temperature loss 1-3K/min (under stable production conditions)

- Backt tilt to empty 100%

- 60-600 molds/hour

Perfect solution for you?

For a profitable and efficient use of the unheated bottom pouring ladle the use case, individual requirements and production properties play a decisive role. The criteria listed below provide a rough guide to check if this system is the optimal solution for you. Please note that these criteria are weighted on a case-by-case basis.

Fully Automatic Pouring or Manual Pouring

pour-tech ladles can be ordered with every level of automatization and are easily upgradable in the future

Continuous operation

- Designed to be refilled every 7-10 min

- Minimizing of temperature loss and magnesium fading

- Can be emptied for longer stops

- Can be heated by burner

Load Cells

- Equipped with pancake load cells to measure weight

- Automatic compensation for ferrostatic pressure variations

- Operators can keep track of remaining iron without opening the lid, loosing temperature

- Weight can be shown on remote location (e.g. melt shop)

Frame Stand and Carriage

- Mounted to a series of frames

- Can travel in every direction (even height changes can be realized)

- Can backtilt

Upgrade to Automation

Upgrade the system to speed up pouring process and work steps to a large extent with less effort at the same time. When talking about automatic pouring, we distinguish between three levels that build on one another.

The unheated stopper pouring ladle can be easily upgraded at any time in order to start with a simple manual system and convert it to a sophisticated, automated system. By adding special features, it may be possible to significantly increase the production output while reducing the manpower to do it.

Semi-automatic pouring

For a solid and constant pouring process in your production.

Automatic pouring

Pouring upgrade leading to a fast, independent and accurate process.

Intelligent pouring

The high-end solution for an intelligent and a self-learning production.

Not the right Product?

View other products or contact us. We also customize products for various use cases!