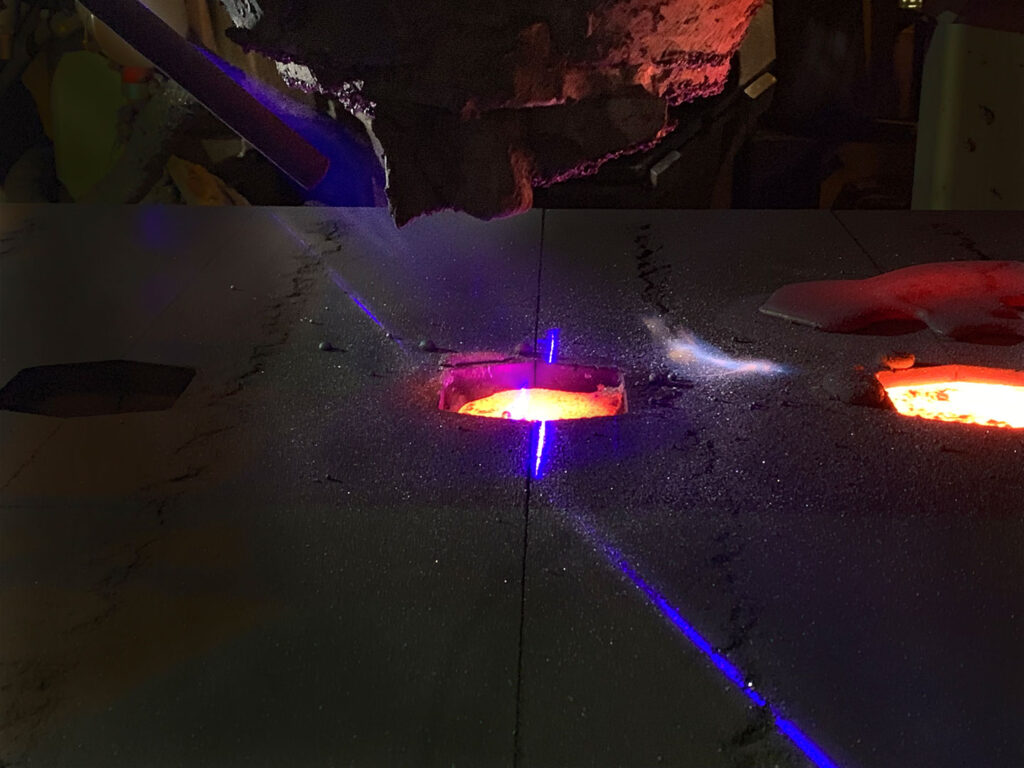

pour-tech AB introduces EASYpour™: the new smart pouring solution in the market

Based on more than 25 years of experience in pouring and Viking Analytics’ know-how of artificial intelligence, pour-tech AB leads to take the next step in automation. The software upgrades already existing pouring systems in an end-to-end automated solution.

EASYpour™controls the pouring in a repeatable manner and is continuously adjusting and optimizing the pour parameters for gradual changes in the process like slag build up, variations in temperature, launder level, conditions of wearing stopper and nozzle.

Niklas Stigendal, General Manager at pour-tech AB, explains why a product that is more advantageous than traditional methods is needed now more than ever:

“The production environment in a foundry is increasingly changing, demanding several adjustments to maintain the quality of the product, sometimes in a matter of minutes. We wanted to remove this complexity for our clients, so the operators could focus on other tasks.”

Niklas Stigendal, General Manager

Before starting the creation of EASYpour™, first a number of challenges were identified. Some factors have a negative influence on the pouring process and are continuously changing:

- imperfect moulds

- slag in the liquid iron

- bath height variations

- temperature changes

Focused on these conditions a sophisticated system was created. In addition to the mentioned minimal operator interference and the use of employees in other areas, foundries benefit by the use of EASYpour™ in terms of product quality – such as perfectly poured molds, constant temperature and no slag in the liquid iron – and reduced production costs as a result.

EASYpour™ is already in operation: For example in Denmark at Vald.Birn A/S

Suitable for gray, mellable, ductile, CGI and mixed production, the system already is successfully in use in Europe. For example, Vald. Birn A/S in Denmark benefits from EASYpour™ since almost a year. By upgrading their pouring system, the foundry has achieved higher quality with less operator involvement in the production of grey and ductile iron. Cost reduction also has been analyzed. Thanks to the automation of pouring first reportings show a gain of 0.10€ per pour.